Since sidewalk and street crossing network is an essential unit of pedestrian mobility, the increased consciousness about inclusivity, and more accessibility problems have come to the fore. This is evident in the increasing number of ADA cases filed in the US district; between 2013 and 2017 as the number of these cases increased by an alarming 100% (5100 to 10733).

The 2018 report1 from the Northwest Pavement Management Association Conference states that most of these cases are employment-related and makeup to 27% of civil rights lawsuits.

In a lawsuit filed against the Oregon Department of Transportation by the Association of Oregon Centers for Independent Living (AOCIL) and eight individuals, the settlement agreement mandated the department to fix missing curb ramps, upgrade existing ones and address accessibility issues over the next 15 years. It is a turning point in the struggle for inclusion in social infrastructure throughout the country.

Details of the settlement2 include:

- An inventory of existing curb ramps to bring, 30% (by December 31, 2022), 70% (by December 31, 2027), and 100% (by December 31, 2032) into full compliance with ADA ramp construction.

- An inventory of pedestrian crossing signals at curb ramp locations to determine their compatibility with ADA guidelines—height and landing, reach.

- A commitment of $5million in initial funds to facilitate the reconstruction of identified curb ramps and pedestrian crossing signals.

The implications of this settlement include unforeseen costs for the replacement of substandard curb ramp constructions, the disbursement of unplanned, settlement funds, legal fees, and more accidents because of poor curb ramp design—leading to even more lawsuits.

This lawsuit has sparked proactivity in fixing accessibility issues with pedestrian facilities, causing districts and transportation departments to budget more funds to evaluate and redesign curb ramps, all while trying to avoid litigation.

Can technology aid the design of curb cuts and CAD drawings, shorten the project time of curb ramp construction, ensure accessibility and inclusion, and prevent lawsuits? The answer is yes.

Inclusion through accessibility is simply the right thing to do

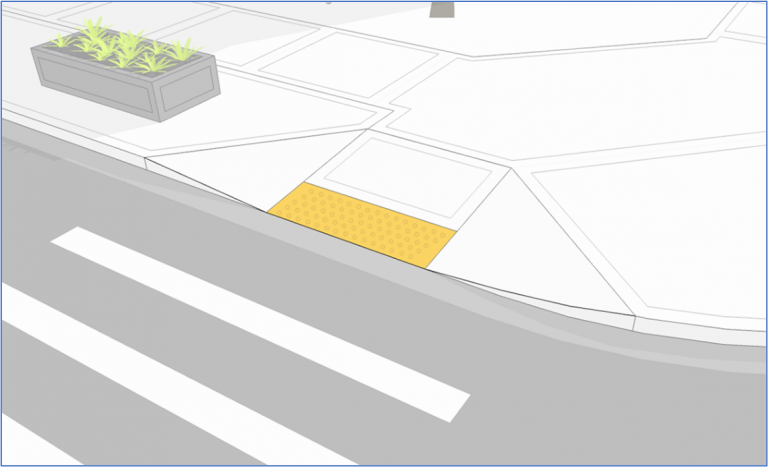

ADA guidelines state that curb ramps must have “at least 36 inches of clear space at the top of the ramp”4 to make room for foot traffic that does not prevent the usage of the ramp. It also stresses that these ramps should not be built “where they will be obstructed by parked vehicles.” ADA ramp construction also requires detectable warnings—to be felt underfoot or with a cane—to cover the width and depth of the ramp run for the safety of curb ramp users.

Jordan Ohlde3, one of the eight individual plaintiffs in the 2016 Oregon lawsuit could only access the road by wheeling his chair on the bicycle lane—a most uncomfortable and potentially dangerous situation. Regarding the 2017 settlement agreement, he says that it will “make Bend more reliable for all citizens, not only for those using wheelchairs but those who use walkers and strollers.”

The ADA reports that 296,658,4755 Americans have ambulatory difficulty. This means that more attention must be paid to accessibility and inclusion in sidewalk design, and any delay in curb ramp reconstruction will bring great discomfort to millions of people who depend on them for motility. Retrofitting substandard curb ramps and building compliant ones is simply the right thing to do.

To design/redesign curb ramps, engineers need to follow guidelines—retrofitting these ramps to specific standards through CAD drawings—and replicate them where they need to be built. This often requires a specific level of skill to achieve and consequently more time and money. Curb ramps (or curb cuts) can cost an average of $1500 each and reworking them can cost as high as $4000 each.

Not only is this process costly, it also takes time and considerable effort. For instance, the 2017 settlement of the Oregon lawsuit directs that the retrofitting of curb ramps be done over 15 years.

This is too much time in between where more accidents could occur, and leave more people depending on this facility to be inconvenienced as they run basic errands, thereby having more lawsuits Getting right is time-saving, cost-effective, and simply the right thing to do.

Here are steps to get ADA ramp construction right at the start of your project;

Shorten curb ramp project times

AQCESSRAMP was developed to help meet ADA compliance with its excellent features that swiftly generate curb ramp geometry based on built-in templates that follow each jurisdiction’s standards. The ability to perform edits via grip points saves time, cost, eliminates tedious repetitions and encourages accessibility and inclusive infrastructure.

There are three major benefits of using AQCESSRAMP:

There are three major benefits of using AQCESSRAMP:

- Adaptability to design/Easy guideline compliance

With AQCESSRAMP, you can quickly adjust your design using the dynamic grip points while ensuring the curb ramp design is compliant with the selected design guideline from all 50 states plus FHWA, ADAAG, and PROWAG included in the software. With its dynamic editing and automatic calculations, you will instantly know if your slopes, cross slopes, and other components are compliant by referring to the warning notifications.AQCESSRAMP is compatible with a host of CAD platforms, including Autodesk® AutoCAD® 2015 – 2021 (except AutoCAD LT), Autodesk® Civil 3D® 2015 – 2021 alignments, Bentley® MicroStation® V8i (SS4 and up), CONNECT® (Update 12 and up), and Bentley® OpenRoads Designer CONNECT (Update 8 and up).

- Ease of customization and report generation

With AQCESSRAMP, you can select a curb ramp template based on the applicable guideline or create your custom template based on the available types. Generate detailed reports that display all the key coordinates, slopes, and elevations tied to the reference alignment with the Station Offset Reports, to ensure all collaborators are carried along with the progress of the curb ramp design. It is also easy to edit geometry parameters, adjust curb cut templates and customize sidewalk designs based on stakeholder feedback; users can click, drag, and drop grip points and/or manually type in precision inputs, ensuring compliance in no time.

- Time management

AQCESSRAMP’s features help to save time on both 2D and 3D modeling while producing accurate, safe (compliant) curb ramp designs that can be adjusted as seamlessly as they were created. It is the sure solution to long hours of curb cut retrofitting, sidewalk design, and billable man-hours.

Using AQCESSRAMP is easy by following these steps:

-

- Select curb ramp template and type.

- Select curb geometry.

- Specify the location.

- 2D plan and 3D model is created with callouts of elevations provided.

- Adjust the dimensions of the ramp until callouts show compliance.

- Generate 3D model and surface.

- Display geometric summary table and point coordinate table for IFC drawing.

*Note – this tool still requires the Project Engineer on Record to exercise sound engineering judgment and practices for final design and approvals

Conclusion

If you are looking to achieve accessibility to ensure that your CAD drawings are suitable for ADA ramp design, to reduce the cost and time of manual retrofitting curb ramps to increase productivity, and could prevent more expensive lawsuits, AQCESSRAMP is your best bet.

Sources

- http://nwpma-online.com/presentations/2018/adalawsuit.pdf

- http://umatillacounty.net/fileadmin/user_upload/DD/ODOT_Notice_of_Proposed_Class_Action_Settlement__Final.pdf

- https://www.bendsource.com/bend/landmark-disability-rights-settlement/Content?oid=3015739

- https://www.ada.gov/pcatoolkit/app1curbramps.pdf

- Disability Statistics | ADA Accessibility Lawsuits and Other Stats – 2020 (akeaweb.com)